2337 Effective Throat of Skewed T-Joints. Notice that the far side weld is less than the 5 16-in.

Designing Fillet Welds For Skewed T Joints Part 1

However many designers are unaware of the AWS D11 skewed t-joint requirements and apply typical 90.

. The effective throat shall be the shortest distance from the joint root to the weld face of the diagrammatic weld see Annex I. Fillet weld size shown in Table 10-14C on page 10-177. That is fillet welded joints are simple to prepare from the standpoint of edge preparation and fit-up.

See Annex II for formula governing the calculation of effective throats for fillet welds in skewed T-joints. Integral extension of the other. The 100 050sin 15 θ term in Equation J2-5 which enables the weld strength to be enhanced when the direction of loading is non-parallel to the axis of the weld.

The directional method is based on the comparison between the design tensile strength and the applied stress in the most severely loaded part of the weld throat. The simplified and the directional methods. Typical welds capable of being measured with gauge 10 are welds 12 and 14 shown in FIGS.

The fillet weld design clauses in AISC 360 Section J24a permit the use of a so-called directional strength enhancement factor for fillet welds ie. A series of equations can be used to determine weld sizes for various angular orientations and required throat. 24 Fillet Welds 241 Effective Throat 2411 Calculation.

Designing Welded Lap Joints. The effective throat of a skewed T-joint in angles between 60 and 30 shall be the minimum distance from the root to the diagrammatic face. For angles between 60 and 80 degrees the designer has to account for the effective throat using the formula contained in Annex B D11.

According to clause 45311 of EN 1993-1-8 design resistance of a fillet weld should be determined using either the directional method or the simplified method. Single-sided fillet welded joint types. W 1 20221 in.

The requirements of 2328 shall apply. Designing Fillet Welds for Skewed T-Joints Part 1. Detailing fillet welds for 90-degree T-joints is a straightforward activity.

Cash app 99 off boost. In the directional method the force acting on the fillet weld is resolved into components parallel and. Fillet weld that is.

Inspection can be challenging due to the actual weld geometries and the undesirable repetitive echoes within the. Designing fillet welds for skewed t joints part 2. There is no specific guidance on which method to use and in practice the choice is usually made on practical grounds.

In order to weld the full thickness of a plate and achieve the weld throat thickness required by design it is therefore necessary to cut away sufficient metal along the joint line so that the welding electrode has access to the root of the joint enabling the root pass to be deposited and then the remainder filled to complete the joint. Fillet welds are probably the most common type of weld particularly in structural steel work applications so this first section will look at some of the design considerations of fillet welds. The article in the last issue of Connect introduced the fillet weld the least costly weld type to make since the components to be joined do not require flame cutting or machining of a weld preparation the pieces can be propped against each other and the welder can then deposit a single pass of weld metal against a solid metal backing.

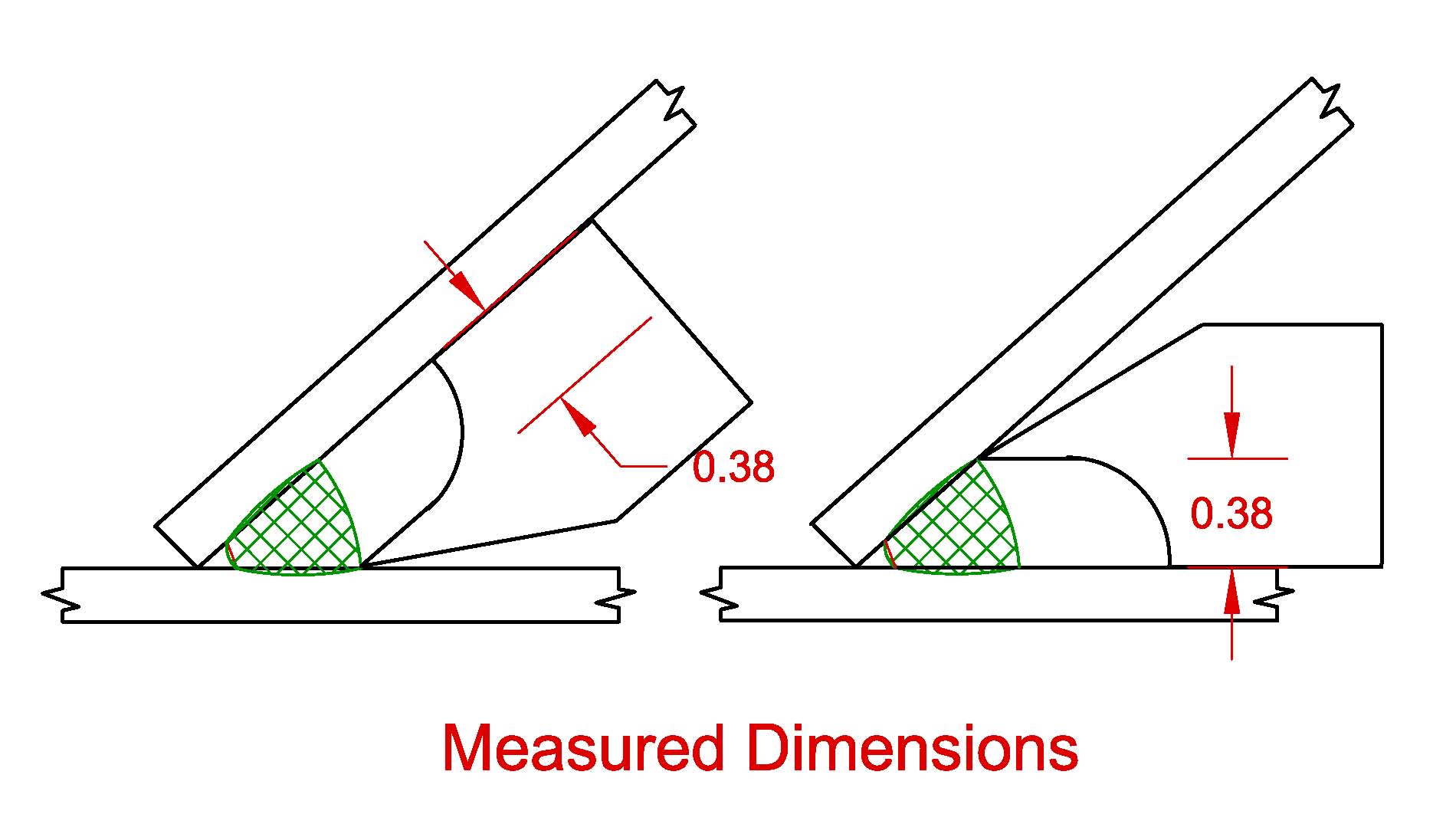

The present invention comprises a gauge for measuring certain dimensions of welds at skewed T joints the gauge. Fillet Weld The required fillet welds are shown in Figure 8. Depending on the skewed t-joint geometry designers are required to define the required weld leg or effective throat size.

Depending on the skewed t-joint geometry designers are required to define the required weld leg or effective throat size. Designing fillet welds for skewed t joints part 2. Weld Fillet or Fillet Weld is a basic type of weld for welding two or three members using a T joint Lap joint or Corner Joint configuration.

Consider the Transfer of Stress through Members. Designing Fillet Welds for Skewed T-Joints Part 1. Notice that the far side weld is less than the 5 16-in.

Sometimes however because of design requirements corner T and cruciform joints are required to be made with butt welds. However many designers are unaware of the AWS D11 skewed t-joint. See Annex II for formula governing the calculation of effective throats for fillet welds in skewed T-joints.

Fillet weld legs determine fillet weld. Fillet welds are not complete penetration welds CJP and weld. Fillet Weld The required fillet welds are shown in Figure 8.

The present invention comprises a gauge for measuring certain dimensions of welds at skewed T joints the gauge being broadly denoted by the numeral 10. The type of weld will depend most on its func-tion. Used to calculate the required fillet weld size for the far side weld.

The American Welding Society Structural Welding Code - Steel AWS D11 provides design and detailing requirements for skewed t-joints. They may be used to make T lap and corner joints Fig4. Our spacious design and attention to detail make Champion Written By colinmathurin25300 Friday May 13 2022 Add Comment Edit.

Other welds include partial penetration groove welds. However many designers are unaware of the AWS D11 skewed t-joint requirements and apply typical 90. Fillet Welds account for the bulk of weld type in every welding construction although they are not used for critical welding joints.

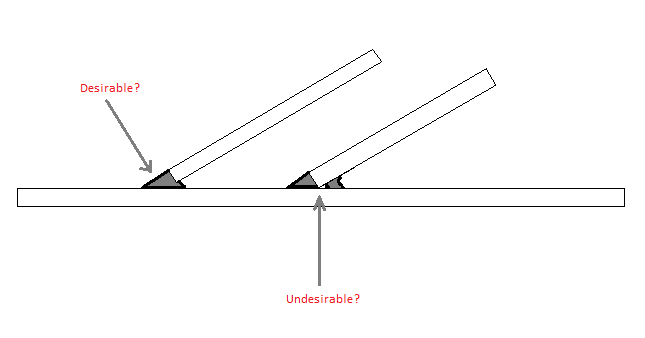

If the dihedral angle is less than 80 or more than 100 degrees it is a welded skewed T-joint. Depending on the skewed t-joint geometry designers are required to define the required weld leg or effective throat size. A tabulation of mea-.

T x W of the theoretical throat design throat thickness and effective weld length as shown in Fig. Cm lan design group. No reduction shall be assumed in design calculations to allow for the start or stop of the weld.

2336 Minimum Skewed T-Joint Weld Size. The strength of a fillet weld is based in the design on the product effective area of the weld. A fillet weld is used around a lap joint and where one plate meets another at or about a right angle a corner or T joint.

Fallbrook ranch apartments prices. Sin 682 0 0247 in. Fillet weld that is.

Or Fig 311 of AWS D11 are considered prequalified for T joints. Lessons Learned in the Field. The effective throat of a skewed T-joint in angles between 60 and 30 shall be the minimum distance from the root to the diagrammatic face.

The term fillet weld is applicable to welds deposited on the joint with dihedral angles between 80 and 100 degrees. Mixing Welds and Bolts Part 2. The American Welding Society Structural Welding Code - Steel AWS D11 provides design and detailing requirements for skewed t-joints.

A weld preparation the weld prep is therefore. Eurocode 1993-1-82005 gives a designer a choice between two methods for the design of fillet welds.

Skew T Fillet Weld Gauge Gauges Weld Welding

Designing Fillet Welds For Skewed T Jointsa Part 1 The James F

0 comments

Post a Comment